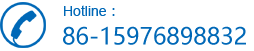

• Our CNC Machining Services

• Our fully certified machinists provide milling, turning, lathing services in our state-of-the-art machine shop. Featuring, the latest CNC Mills and CNC Lathes to cut steels, composite materials, exotic metals, aluminum, and plastics. We maintain the highest standards of professionalism and quality in order to ensure our clients are completely satisfied.

• At POMO, tolerances are controlled to DIN-2678-1 Fine for metals and Medium for plastics as standard for CNC prototypes.

• The biggest advantages of our CNC Machining

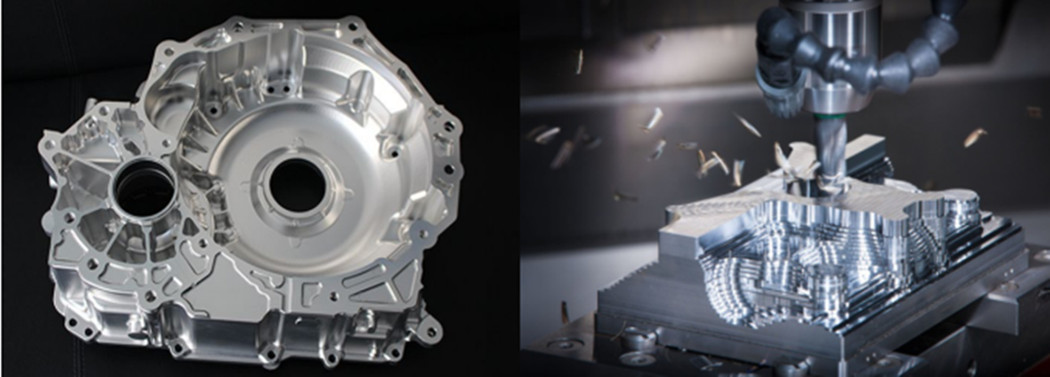

• We use modern CAD/CAM software that shortens the time of preparing a quote,programming and reduces the risk of errors.

• Advanced cutting tools to ensure the highest efficiency, quality and aesthetics of manufactured parts (this is particularly important in the production of parts from aluminium which are then anodized)

• Our machine park consists of precise and reliable machine tools of renowned companies: Frank, Fanuc ,Taiqun nd Chiron

• We make the equipment ourselves – this way we are able to reduce the costs and shorten the service lead time.

• We advise our clients to improve the economic efficiency of production of CNC milled parts

• We use modern measuring instruments, including coordinate measuring machines (CMM) and optical devices to be absolutely certain about the accuracy of measurements

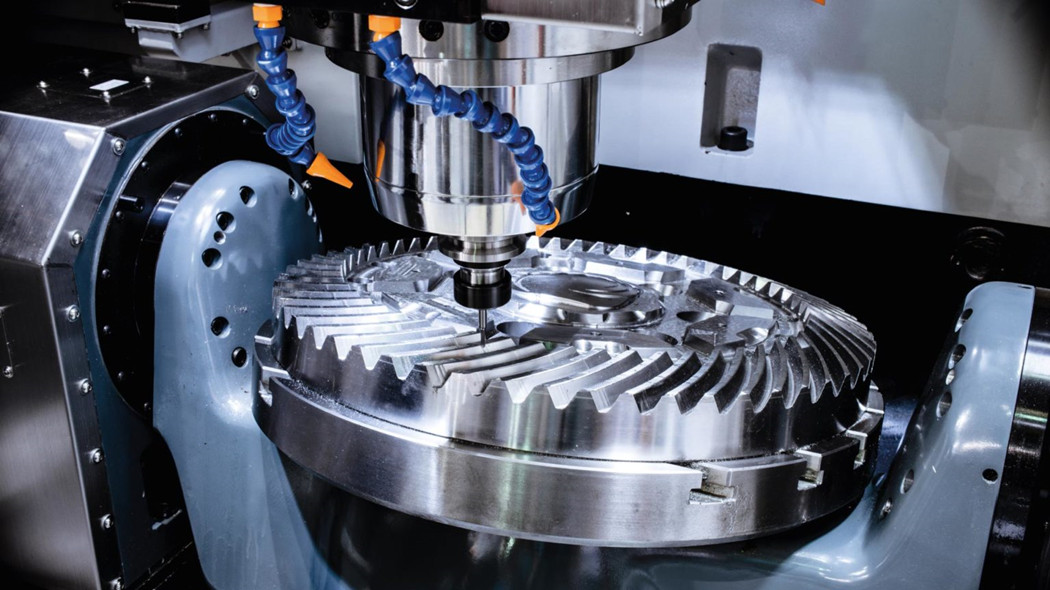

• Custom CNC Machining Is Used For

• Precision CNC machining parts and rapid prototyping, metal parts, performance plastics, and low-mid

volume rapid machining production runs.

• When it comes to China CNC machining or custom CNC machining in general, our approach is: provide

highly flexible rapid low volume manufacturing solutions that deliver superior parts, fast.

Our CNC Machining Gallery

• 30+ CNC Machines with 3, 4,5 axis.Such as Frank,Taiqun.

• Materials List

• Plastics – ABS, POM, PC, Nylon, 30% Glass fibre Nylon, Black ABS, PP, PE, . TEFLON, PPS, etc.

• Metals – Aluminium, Stainless Steel, Carbon Steel, Zinc, Brass, Copper, Bronze,Cast Iron, etc.